The cardboard scraps / strips to be shredded are fed to the cardboard fine ripper via an on-site conveyor. The material is caught by the shredder rotor, torn at the comb stator and discharged downwards onto a cross conveyor, which transports the shredded material onto another on-site conveyor.

The machine is equipped with fixing blocks and a position switch and can only be operated when the machine is accurately positioned, secured with the clamping lock and the position switch is occupied. Electrical control / connection via Harting plug to the punching machine.

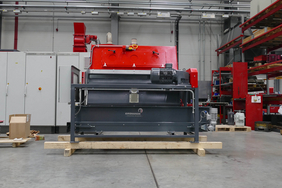

Fine cardboard shredder FKZ1600

Intended use: shredding for the purpose of piece size reduction; punching remnants with dimensions 1080 x (35-70) x 0.66mm (LxWxH); approx. 5000 strips/hour