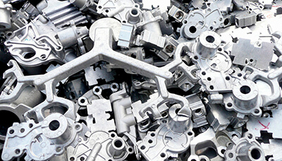

In aluminium foundries in particular, large quantities of punching waste, flashings or defective castings are created in the daily production, which are then collected, recycled and melted down again. Especially in view of rising commodity prices, it is in the interest of companies that the return of waste material to the production process takes place as quickly and efficiently as possible. Since many parts are bulky and unwieldy, they must be broken down before remelting.

The recycling experts at ERDWICH Zerkleinerungs-Systeme GmbH are presenting two solutions from their portfolio at this year‘s GIFA in Düsseldorf, namely the RM1350/2 twin-shaft ripper and the M600/1 single-shaft shredder, with which this pretreatment can be carried out.

Recycling in the foundry industry with Erdwich

GIFA2019_Erdwich_E.pdf (305 KB)