The reduction of transport costs, the reduction of material for feeding to existing press containers or balers as well as the shredding of material for conveyor belt feeding are good reasons for the use of cardboard shredders. With the EKZ cardboard shredder and FKZ fine cardboard shredder, we have two robust and absolutely reliable machines in several sizes in our product portfolio. Whether it is the shredding of packaging or the preparation of cardboard waste for suction into existing conveying systems, we always offer you a perfect solution tailored to your needs.

Ripper segments reduce size to less than one tenth

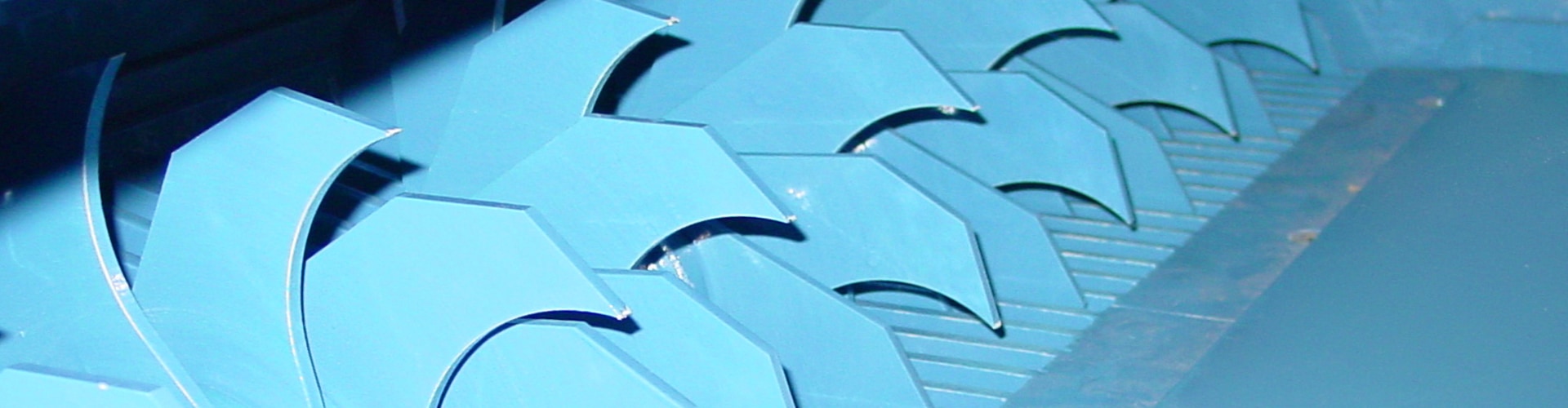

The EKZ cardboard shredder consists of two shafts with independent drives, a slow-running infeed shaft and a faster ripper shaft, which shreds the cardboard boxes into the desired size. Segments of wear-resistant special steel are used for this purpose, which are arranged on the shredder rotor in such a way that they point alternately obliquely outward and inward. In this way, the rotation of the shaft produces a wobbling motion that ensures the desired shredding effect. The rotors, which are very large at 520 mm in diameter, also process large-format cardboard without any problems. In addition, the infeed and shredder rotors are equipped with a special scraper system that prevents the shaft from wrapping and ensures a stable material feed.

Stable design for long service life and high availability

In general, the plant is designed for the highest possible operational reliability with long maintenance intervals. Chain drives are used for power transmission. This allows individual speeds to be selected for the feed rotor and the ripper rotor, matched to the material. Since this is a slow-running machine, the chains themselves have a long service life and low relubrication requirements. A PLC control system with automatic reversing and shutdown also protects the shredder from damage caused by overloading or solid particles in the material. The EKZ is available in various designs for integration into the process line. For example, with an attached feed table as a floor-mounted unit for manual feeding or as a vertical version for installation above press systems or in discharge chutes. The shredder can also be individually connected to the downstream transport route, for example by means of control parameters or level measurements.

Process-safe fine shredding of cardboard waste for direct suction into conveyor systems

Our FKZ fine cardboard shredder is the ideal complement to the EKZ cardboard shredder. Due to its efficient shredding process, it is perfectly suited for trouble-free suction directly at the point of accumulation. Material such as cardboard waste from production machines or die-cutting machines can thus be sucked off directly into existing conveying systems. This enables us to offer you a complete system for the highly efficient processing of cardboard waste. Different sizes allow for an economical machine design tailored to the respective volume.

► Simple maintenance

| Due to individually bolted, replaceable feeder and ripper segments.

| Low maintenance chain drives.

In addition to our proven EKZ, another machine has been developed to shred cardboard waste to a piece size. This enables pneumatic disposal directly at the material accumulation point. The FKZ fine shredder is ideally suited for processing punching remnants or individual sheets from cardboard production. By using the ERDWICH FKZ fine cardboard shredder on your production machine, in-house disposal of filled waste containers is no longer necessary. This saves time and costs and also ensures a smooth process flow for you.

![[Translate to Slowakisch:] [Translate to GB:] Detail Reisserwellen Erdwich EKZ](/fileadmin/user_upload/02-Maschinen/Karton-Zerkleinerer/Kartonagen_Zerkleinerer_EKZ1800__2_.jpg)

![[Translate to Slowakisch:] [Translate to GB:] Erdwich karton-Zerkleinerer EKZ](/fileadmin/user_upload/02-Maschinen/Karton-Zerkleinerer/Kartonagen_Zerkleinerer_EKZ1800__1_.jpg)